Aside from the leaky roof the other most time sensitive matter is a lack of heat in the house.

The previous owners heated with wood, in a wood stove downstairs that the gentleman built a bizzare sheet metal contraption around that fed some makeshift ductwork.

In the next pic you can also spot the (???) auxiliary hot water tank that I BELIEVE he was trying to use the wood stove to help heat??

Well, like everything else in the house, they neglected it, and due to creosote build up in the chimney from it not being swept, they had a chimney fire. When the fire department came and sprayed water down the chimney to put it out, it shattered the liner and did some other damage making the wood heat unusable. That means no heat of any variety in the house.

So I had a couple of options:

1. Replace the chimney and once again use wood heat. Not a great option for me, as insurance companies do not like wood heat, making it difficult and expensive to obtain house insurance, plus I work sometimes long hours meaning no one would be around to feed the fire.

2. Remove old stove and heat with electricity, be it a heat pump or electric furnace. Also not a good option for me for a couple of reasons: I only have 100A service to my house. I explored the idea of getting a service upgrade and it would be very, very costly and present some other issues. Electricity is also quite expensive to heat with, and while heat pump technology is evolving and getting better, it gets VERY cold in my area in the winter and heat pumps struggle to keep up.

3. Heat with a gas appliance. I'm way out in the boonies and there is no natural gas service available here, BUT, there are companies that will stick a large propane tank on your property, pipe it into your house, and then truck propane to you as you need it. The company that I selected even automatically keeps track of the level of the tank and will schedule deliveries so you don't run out, making it roughly equivalent to having natural gas. I like gas appliances so this was the obvious choice for me, only catch being you have to put the tank somewhere, it has to be at least 10 feet from structures, and they require that you have a trench ready to go for them to run the gas line into your house.

So, I need to dig a big trench. I decided to tuck my tank at the treeline between my house and the road somewhat along this pink line.

The idea with this particular choice is in the future if I ever wonder where my buried line is, I can just look down the side of my house to the treeline and that's where it'll be, square with the side of the house.

Now I need something to make the trench. I COULD rent a machine, dig the trench, have the propane people come, run the line, and backfill it by hand. That would cost a couple thousand dollars. For a couple thousand more ($5600 total), I was able to purchase this 1.2 ton chinese mini excavator.

Its a Machpro MP15, which is a modified and rebranded Rippa R319. Cute little guy with a full cab that even fits me, 13.5hp Briggs & Stratton knockoff engine and already set up for auxiliary hydraulic attachments like a hydraulic thumb or augur or the like.

It's going to be a great little machine to have on the acreage, when you own a bit of land there's always some outside chore that needs doing that a piece of machinery would be really helpful for. This won't be the last trench I dig, I assure you.

I have only used this machine a total of under an hour (edit: I'm finally finishing this post a week later, and my assessment absolutely holds) but it's amazing. When I got it home I immediately fired it up and dug a little practice trench, just to see what it was capable of.

I could not stop grinning. This thing is so much fun to operate. You truly feel just like you are operating a larger excavator. When I finished roof work for the day and the bugs tried to drive me inside, I fired up the excavator and got stared on that trench.

This truly is an awesome little machine. The soil is rocky and ugly, it would be a terrible experience trying to hand dig here. But it's no match for the little mini ex. Sure it's slow going and it doesn't always have the power to pull out a full bucket edit 2: I solved that, more later in the post), but for a little guy, he puts in the WORK.

It's been a very pleasant couple of hours working with him and I'm really looking forward to more trenching. As my father said to me when I was talking about it, I'll constantly be looking for projects I can use it for now, indeed the only reason I stopped for the evening was because it hit 9PM and I didn't think my neighbours would appreciate hearing the roar of the knockoff Brigs anytime past then.

Alright 1 week of collecting pictures and stories about this thing and I'm finally getting back to completing this post. First thing I did the next day before getting into some more digging was correct the power issue. The engine had plenty of juice left, but there was a hydraulic bypass safety valve that was set too low.

Thankfully the internet directed me towards the issue and once there I was able to follow Machpro's own procedure in their manual (basically extend the boom cylinder fully, keep the lever pushed for 5 seconds, and if the engine doesn't almost stall, set the bypass higher half a turn. Rinse and repeat until happy. This adjustment easily tripled the digging power from what it was when it arrived.

That done, I got to trenchin' in earnest.

I've only ever run an excavator once before in my life so it took a little time before I was digging with confidence and using the machine like it should be (little tricks like keeping the undercarriage pointed backwards so when using the blade as a stabilizer, it tilts the ex forward and lets you trench deeper) but once I got it mostly figured, I walked it around my dirt pile to the house to dig out the planter.

There is a kind of a planter around a couple of the sides of the house that's basically just an auxiliary wall. The excavator was basically the perfect size to dig between the foundation and the planter, any bigger and the bucket would not have fit.

Although they advertise the max digging depth as 6', it's closer to 5', still mighty impressive for a machine this size.

At one point, a friend came over and I got this little clip of her running the machine.

https://youtu.be/eot4Fa89sAU

As I got closer to the treeline, I realized that I'd spray painted my line right to a huge piece of concrete that was just laying there. No matter, it was no match for the mighty mini.

That obstacle gone, I decided to press into the forest a bit, all of the brush you see is just brush, the mature trees are several feet back, and at some point I think I'd like to fight the brush back a little ways to the line of actual trees. There was also an apple tree which I elected to remove, I love trees but fruit trees do not have a place on my property as they are strong bear attractants and I live in the midst of bear country. The previous owner was telling me how in the fall there are 6-8 bears climbing around the apple trees on any given day, not something I'd like to deal with. Anyways, I don't have a chainsaw handy, but I DO have a sawzall and a wood blade so,

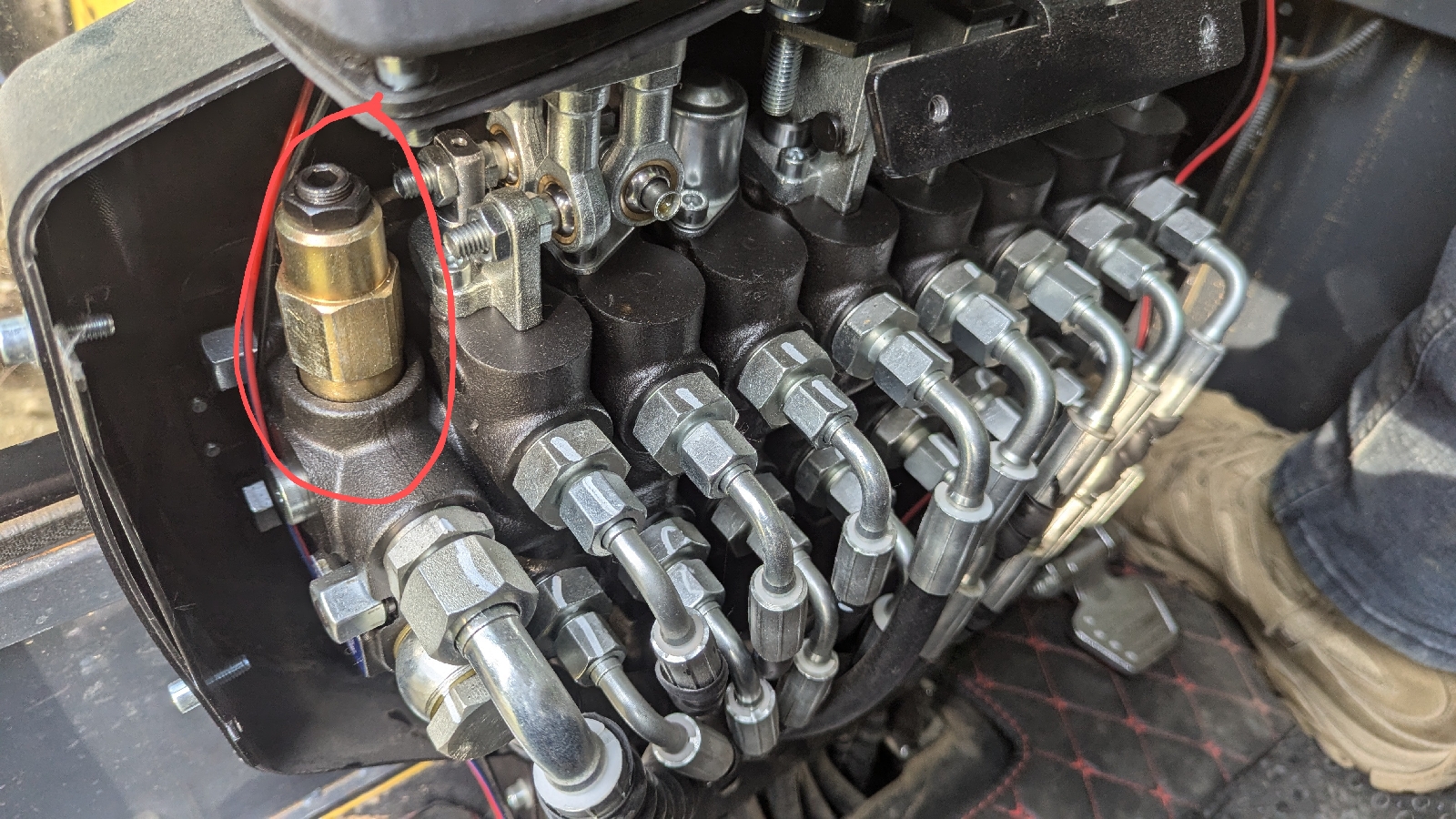

At this point, disaster struck. Inexperienced operator that I am, while dragging the stump out, I dumped it clean onto the hydraulic cylinder for the backfill blade and snapped a hydraulic hose.

This is quite the issue because the way the system is designed in this machine, the return pressure passes through the entire system on its way to the tank, which means any time I operated ANY function, pressure came spewing out of this break. Well, off to town to see if I can find a cap that matches the broken end.

Unfortunately I had no luck sourcing a fitting. These machines use DIN connections for their hydraulics which are metric and none of the stores carry metric fittings. But I have to get the machine running again to finish the trench cause the propane people will be here in 2 days.

Well, desperate times call for desperate measures. I took the busted hose end home, popped the little O ring off and welded the end solid. No prep, galvanized steel, flux core welder.

With it now a plug, I located the valve that drives the cylinder and used my homemade plug on it.

The only twist here being that valve body is aimed straight at my nuts when I'm operating and I don't REALLY trust my aforementioned no prep welding under hydraulic pressures. I'm not looking to have a hole drilled clean through me if that springs a leak.

It was however good enough to let me stand beside it and walk the machine back to where I have power and weld up the busted end of the hose.

Now, if it leaks, it'll just shoot more fluid outside the cab and my nuts are safe. Back to digging.

While clearing out the brush around the trench, I used the mechanical thumb for the first time. Though a hydraulic thumb would be much nicer, this mechanical thumb is certainly very utilitarian and effective.

With the trench dug full length although needing a bit of cleanup I turned my attention to some planter removal. Out comes the SDS-MAX rotary hammer.

(I also ended up having to break the other side as I couldn't quite get the full chunk out in one piece.)

Tossed some plywood over the trench and saved my back lifting with the excavator.

The last two steps were digging out the dirt that was present under the concrete between the two holes,

And going over the trench once more, smoothing out the bottom at max digging depth. To do this I just kept hopping out and moving a piece of plywood from the front to the back and then backing over it.

This made the trench smooth, got all the larger rocks that spilled down when I was digging out, and allowed me to re dig a section where the walls sloughed in a bit.

One 100 foot long 5 foot deep trench allllllll done.

The propane line will just run from one end to the other, but it would be a crime to waste a beautiful trench to the treeline like that, so I'm also burying a 3" conduit for future considerations. To make pulling new things through the conduit maximally easy, I'm going to core a hole through my foundation at bottom of the trench and go straight out and down, meaning the long pull will be a straight 100' shot followed by a single 90 up at the trees. To line it all up, I drilled a tiny pilot hole through the wood above the foundation and used a plumb bob and tape measure to sort out where on the inside I should drill from.

Now that I'm all ready for propane, it's time to circle right back to the beginning and remove that monstrosity of a heater downstairs.

I cut it to be able to reuse some of the ducting if I need to but I don't think I will. It has accumulated a truly breathtaking amount of dust over the years and I'd prefer not to blow that all over the house. Once I have the furnace to bring in and set up, I'll make a decision.

Phew that was a long one. If you are still with me, congrats on making it through! Till next time :)

Comments

Post a Comment